I-CNC eyenziwe ngezifiso ipuleti le-graphite

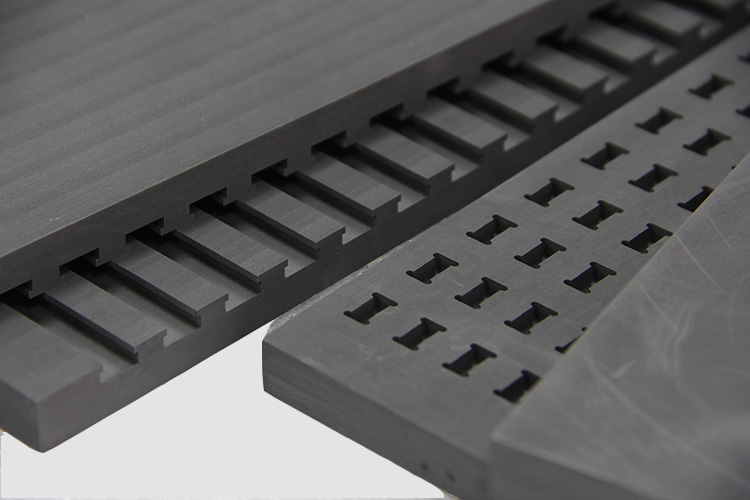

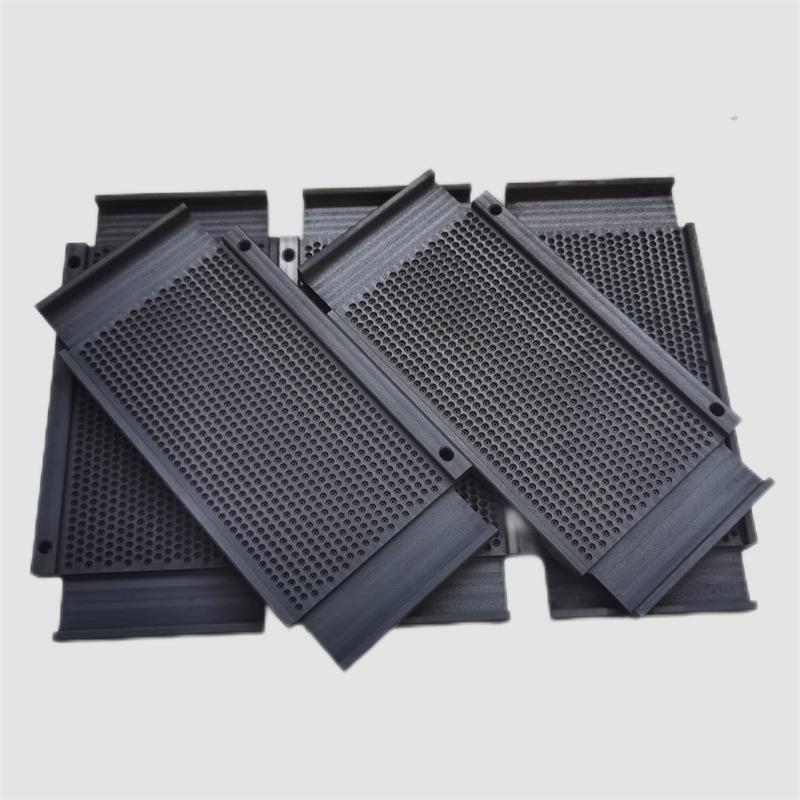

Izici

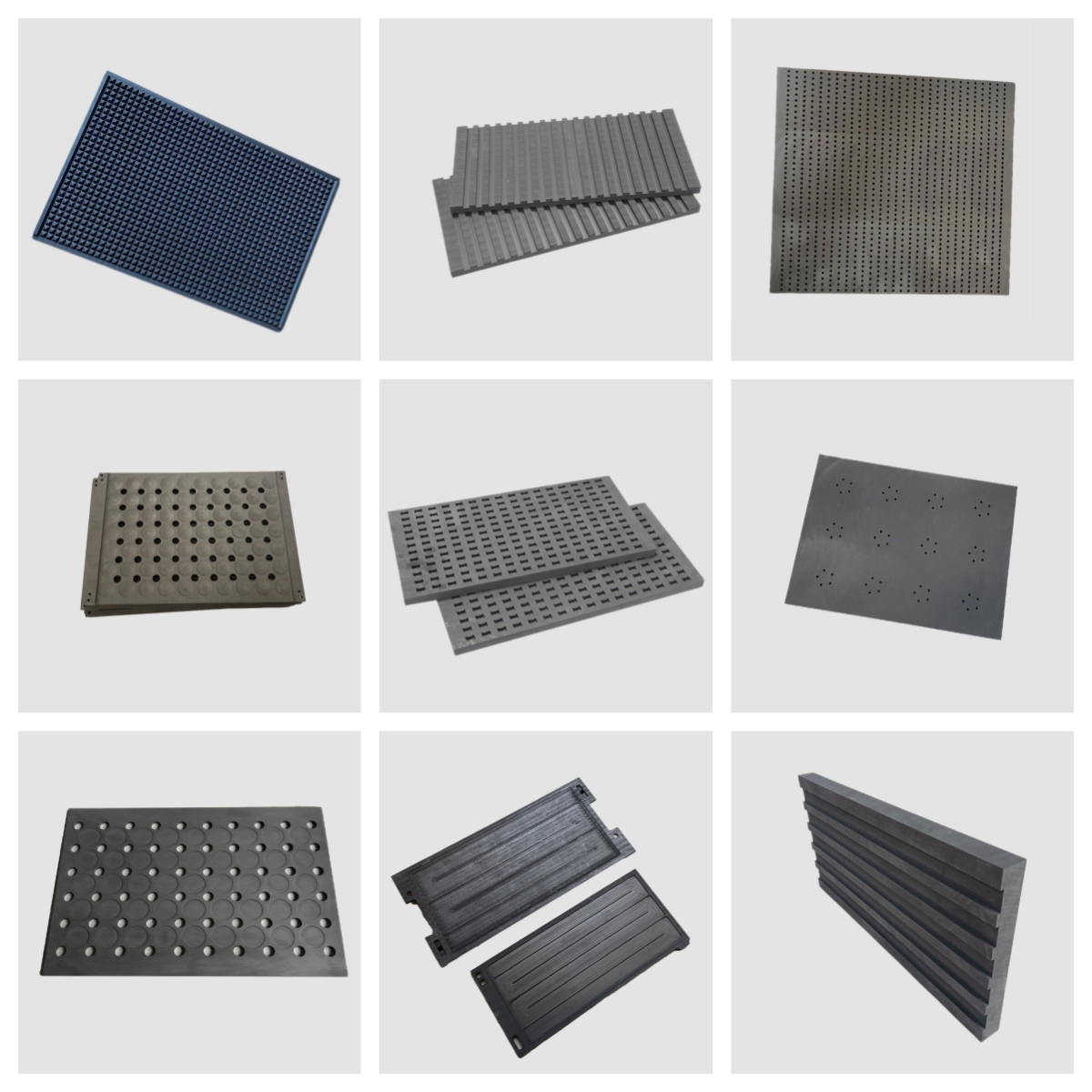

I-1) Izinto eziphikisayo: Embonini yokuncibilikisa, amapuleti e-graphite asetshenziselwa ukukhiqiza ama-graphite crucibles, njengama-ejenti okuvikela ama-ingots ensimbi, nanjengezitini zekhabhoni ze-magnesia zolwelwesi lwezithando zokuncibilikisa.

2) Izinto zokuqhuba: Embonini kagesi, i-graphite isetshenziswa kabanzi njengama-electrode, amabhulashi, amashubhu ekhabhoni, kanye nezingubo zokumboza amashubhu kamabonakude.

3) Gqoka izinto ezimelana nezinto zokuthambisa: Emishinini eminingi eyimishini, amapuleti e-graphite asetshenziswa njengezinto ezingagqoki futhi zokugcoba, ezingashelela ngesivinini esingu-100m/s ngaphakathi kwebanga lokushisa elingu-200 kuye ku-2000 ℃ ngaphandle noma ngokusetshenziswa okuncane amafutha okugcoba.

4) Izinto zokuvala: Sebenzisa i-graphite eguquguqukayo njengama-piston ring gaskets, izindandatho zokuvala, njll. kumaphampu aphakathi nendawo, izinjini zamanzi, izinjini zesitimu, nezinto zokusebenza ezithutha imidiya egqwalayo.

5) Izinto ezikwazi ukumelana nokugqwala: Isebenzisa amapuleti e-graphite njengemikhumbi, amapayipi, nezinto zokusebenza, ingamelana nokugqwala kwamagesi agqwalayo ahlukahlukene kanye noketshezi futhi isetshenziswa kabanzi eminyangweni efana ne-petroleum, amakhemikhali, kanye ne-hydrometallurgy.

I-6) Ukufakwa kwe-thermal, ukumelana nokushisa okuphezulu, nezinto zokuvikela emisebeni: Amapuleti e-graphite angasetshenziswa njengamamodareyitha e-neutron kuma-reactors enuzi, kanye nama-nozzles, ama-cone, izingxenye zemishini ye-aerospace, izinto zokushisa ezishisayo, izinto zokuvikela imisebe, njll.

1. I-isotropy enhle, izici ezizimele ngosayizi, ukuma, kanye nesiqondiso samasampula;

2. Ukwakheka okufanayo, ukuminyana, kanye nekhono eliqinile lokulwa ne-antioxidant;

3. Ukuzigcoba okuhle kakhulu;

4. Ukumelana kahle nokugqwala kwamakhemikhali;

5. Ukusebenza okuphezulu kwe-thermal kanye nokusebenza kokuzinza kokushisa;

6. Amandla anele emishini kanye nokumelana nomthelela;

7. Kulula ukwenza umshini futhi ingacutshungulwa ibe yizimo ezihlukahlukene zejometri ngokuvumelana nezidingo.

Uma usebenzisa iphampu entsha, naka isiqondiso senjini futhi ugweme ukuyixhuma ukuze ihlehlise igiya.Ukuzungezisa emuva okude kwephampu kuzolimaza ama-blade.

Uthuli oluningi endaweni yokusebenza yephampu kanye nokungahlungi komoya okunganele kungasheshisa ukuguga kwe-blade futhi kunciphise ukuphila kwe-blade.

Izindawo ezinomswakama zingabangela ukugqwala kuma-blades kanye nezindonga ze-rotor slot.Lapho uqala ipompo yomoya, izingxenye ze-blade akufanele ziphonswe ngaphandle, njengoba ukucindezeleka okungalingani kungalimaza ama-blades.Ezimweni ezinjalo, ama-blades kufanele ahlolwe futhi ahlanzwe kuqala.

Ukushintsha njalo ngenkathi usebenzisa iphampu kwandisa inani lemithelela ngesikhathi sokukhishwa kwe-blade, kunciphisa isikhathi sokuphila sama-blades.

Ikhwalithi ye-blade engalungile ingabangela ukwehla kokusebenza kwepompo noma ukulimala ezindongeni ze-cylinder, ngakho-ke kufanele kugwenywe.

1. Ikhono eliqinile lokucubungula, elikwazi ukunikeza ukucaciswa okuhlukile kanye namapuleti e-graphite ahlanganisiwe.

2. Singahlinzeka ngemikhiqizo ye-graphite yokubunjwa kwe-extrusion, ukubunjwa kokudlidliza, ukubumba, nokubunjwa kokucindezela kwe-isostatic njengoba kudingeka.

3. Ngokwezidingo ezihlukene zobuchwepheshe, imikhiqizo ye-graphite efana namapuleti e-graphite ingabhekana nokwelashwa kokumelana ne-oxidation, ukwelashwa kokungakwazi ukungena emanzini, nokwelashwa okuqiniswayo ukuze kuthuthukiswe ukusebenza kwabo nokuphila kwesevisi.