Kunomehluko obalulekile phakathiI-Silicon Carbide CarbideFuthi ama-graphite ama-graphite ezicingweni eziningi ezinjengezinto zokwenziwa, izinqubo, ukusebenza, kanye namanani. Lo mehluko awuthinteki kuphela inqubo yaso yokukhiqiza, kodwa futhi unquma futhi izimo ezisebenza kahle nezicelo.

umehluko omkhulu

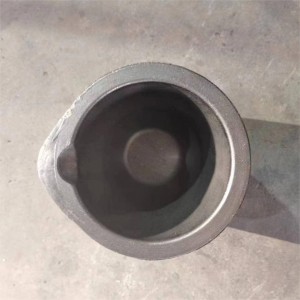

Ama-graphite ama-brucIbles akhiwa ikakhulukazi nge-flake yemvelo futhi asebenzise ubumba njenge-binder. Le nhlanganisela inika i-graphite ebekiwe yokuvuselelwa okushisayo okushisa kakhulu kanye nokumelana okuphezulu kokushisa, okwenza kulungele izinhlelo zokusebenza ezinqubweni zokuncibilika okushisa kakhulu. Isakhiwo esiyingqayizivele kanye nokuvuselelwa okuphezulu okushisayo kwe-graphite yemvelo ye-flake kwenza ama-graphite ama-graphite adume kakhulu kwizimboni ze-metallurgical nezamasizinda.

I-Silicon Carbide enokwemba isuselwa kugrafu ye-flake yemvelo, nge-silicon Carbide njengengxenye enkulu kanye ne-resin ephezulu yokushisa i-resin njenge-binder. Njengezinto eziphikisayo, i-silicon carbide inokungamelana kahle kakhulu nokuqina okushisayo, okuvumela ama-carbide e-silicon carbide ukuthi asetshenziswe ezindaweni ezinokhahlo ngokwengeziwe. Ukusetshenziswa kwama-resin angashisa aphezulu nakho kuthuthukisa amandla okuqina okuthe xaxa nokuqina.

Ukucubungula umehluko

Inqubo yokukhiqiza ye-graphite ebekiwe kakhulu ethembele kakhulu ekucindezelweni kwezandla nangokomshini. Ama-graphite ama-graphite amancane akhiwa ngokucindezela kwemishini, abese ekona ku-kiln ekushiseni okuphezulu kwama-degree ayi-1 000, futhi ekugcineni ahlanganiswe nopende wokulwa nokugqwala wokulwa nokuwohloka. Le nqubo yendabuko, ngenkathi isebenza kahle, inemikhawulo ngokuya ngokusebenza kahle kokukhiqiza kanye nokuvumelana kwekhwalithi.

Inqubo yokukhiqiza ye-Silicon Carbitible ithuthuke kakhulu, isebenzisa imishini yokucindezela e-Isstatic nefomula yesayensi. Ubuchwepheshe bokucindezela oku-Isstatic buza ingcindezi efanayo (kufika ku-150 MPA), okuholela ekubumbeni okuphezulu nokuvumelana kokunye okubekiwe. Le nqubo ayigcini nje ngokuthuthukisa amandla aseC ercucible Meshinical, kepha futhi ithuthukisa kakhulu ukumelana kwayo kokushaqeka okushisayo kanye nokugqwala.

Umehluko wokusebenza

Ngokuya ngokusebenza, kunomehluko obalulekile phakathi kwe-graphite rucibles kanye ne-silicon Carbide Carbide Carbibles. I-Graphite Crucibles inobude be-13 ka / cm², kuyilapho amabhulukwe e-silicon Carbide anobunzima be-1.7 kuye ku-26 ka / mm. Impilo yenkonzo yama-graphite ama-gruxibles imvamisa i-3-5 izikhathi ze-silicon Carbide Carbibles, ikakhulukazi ngenxa yokuqina kwezinto ezibonakalayo kanye nokuphikiswa kokugqwala kwe-Silicon Carbide Carbibles.

Ngaphezu kwalokho, umehluko wokushisa phakathi kwangaphakathi nangaphandle kwe-graphite ebekiwe cishe ama-degree angama-35, ngenkathi umehluko wokushisa we-silicon Cardible ungokwezinyathelo ezi-2-5 degrees kuphela ngokuqina kokulinganisa kokushisa kanye nokuqina okushisayo. Ukumelana ne-acid kanye ne-alkali nokuphikiswa kokugqwala kwama-silicon Carbide ama-Carbide ama-Carbide ama-Carbide ama-Carbide aphakeme kakhulu kunaleyo yama-graphite amabala, athuthukisa kakhulu ukusebenza kahle kwamandla futhi asindise ngama-50% ama-crucibles.

umehluko ngentengo

Ngenxa yokwehluka kwezinto zokwenziwa kanye nezinqubo zokukhiqiza, ama-graphicte ama-grucibles kanye ne-silicon Carbide ama-Carbide Brucibles nawo ahlukile kwentengo. Imvamisa, ama-Silicon Carbide ama-Carbide ama-Carbide acishe abe kathathu kunama-graphite ama-graphite. Lo mehluko wentengo ukhombisa izinzuzo ezibalulekile ze-Silicon Carbide Carbible ngokuya ngezindleko zezinto ezibonakalayo, ukukhiqiza inqubo eyinkimbinkimbi nokusebenza.

Ngamafuphi, yize amabhulukwe e-Silicon Carbide ebiza kakhulu, ukuqina kwawo okuphezulu, ukumelana nokugqwala, kanye nokusebenza kahle kwamandla kubenza bakhethe imali ebiza kakhulu yezinhlelo zokusebenza eziningi ezifunwayo. Ama-graphite ama-brucibles ahlala asetshenziswa kabanzi kuzinhlelo eziningi zendabuko ngenxa yezindleko zawo eziphansi nezakhiwo ezinhle eziyisisekelo. Izinzuzo ezifanele kanye nokubi kwalezi zinwele ezimbili zinquma ukuthi zilungele izimo ezihlukile zohlelo lokusebenza.

Isikhathi sePosi: Jun-13-2024