I-graphite crucibleszingamathuluzi abalulekile ezimbonini ezihlukahlukene, ikakhulukazi ezinqubweni zokuncibilikisa insimbi kanye nokuhlanza. Nokho, ukuphatha okungalungile kungaholela ekulimaleni noma ezingozini zokuphepha. Ukuqinisekisa impilo ende nokusebenza kahle kwe-graphite crucibles, kubalulekile ukulandela izindlela zokuphatha ezifanele. Nazi ezinye iziqondiso okufanele uzicabangele:

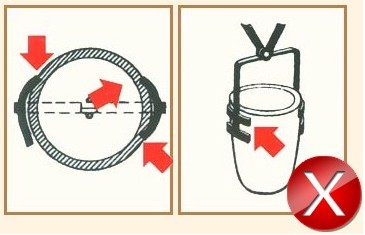

Imikhuba Engalungile:

Ukusebenzisa izindlawu ezincane ezihlabayo kungabangela amazinyo nama-indent endaweni ye-crucible, ikakhulukazi uma kusetshenziswa amandla amaningi ngesikhathi sokubamba. Ngaphezu kwalokho, ukubeka izindlawu phezulu kakhulu ngenkathi ususa i-crucible esithandweni kungabangela ukuphuka.

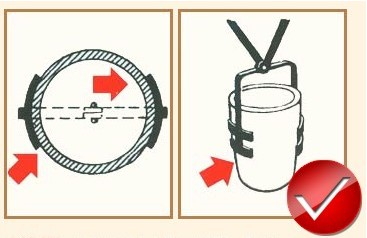

Izinqubo Ezilungile:

Izindlawu ezihlabayo kufanele zibe nosayizi ofanele ukuze zifane ne-crucible. Izindlawu ezincane kufanele zigwenywe. Ukwengeza, lapho ubamba i-crucible, izindlawu kufanele ziyibambe ngaphansi kancane kwesikhungo ukuze kuqinisekiswe ngisho nokusabalalisa amandla.

Ukuze uvimbele ukulimala kwe-crucible ngaphambi kwesikhathi kanye nezingozi ezingaba khona, kubalulekile ukunamathela kulezi zinyathelo zokuphepha ezilandelayo:

Izilinganiso zamathongo ahlabayo kufanele zihambisane nosayizi we-crucible, ukuqinisekisa ukuthintana okuphelele nengaphakathi le-crucible.

Isibambo samathongo akufanele sibe nengcindezi engxenyeni engenhla ye-crucible ngesikhathi sokubamba.

I-crucible kufanele ibanjwe ngaphansi kancane kwesikhungo, okuvumela ukusabalalisa kwamandla afanayo.

Ukwemukelwa kanye Nokuphathwa Kwezinsimbi Ze-Silicon Carbide Graphite

Ukwamukelwa Kwempahla: Lapho uthola izinsimbi ze-silicon carbide graphite crucibles, kubalulekile ukuhlola iphakheji yangaphandle ukuze uthole noma yiziphi izimpawu zomonakalo. Ngemuva kokukhipha izinto, hlola indawo ye-crucible ukuze uthole noma yikuphi ukukhubazeka, ukuqhekeka, noma ukulimala kokunamathela.

Ukuphatha I-Crucible: Ukuzijwayeza Okungalungile: Ukuphatha i-crucible ngokuyishaya noma ngokuyigingqa kungabangela umonakalo kungqimba olucwebezelayo.

Ukuzijwayeza Okulungile: Ama-crucibles kufanele aphathwe ngokucophelela kusetshenziswa inqola ene-cushion noma amathuluzi okuphatha afanelekile ukuze kugwenywe ukuthintana, ukungqubuzana, noma ukuwa. Ukuze uvikele ungqimba olucwebezelayo, i-crucible kufanele iphathwe ngobumnene, iqinisekise ukuthi iyaphakanyiswa futhi ibekwe ngokucophelela. Ukugingqa i-crucible phansi ngesikhathi sokuthutha kufanele kugwenywe ngokuqinile. Ingqimba ecwebezelayo isengozini yokulimala, okuholela ekuphumeni kwe-oxidation nokuguga ngesikhathi sokusetshenziswa. Ngakho-ke, kunconywa ukusebenzisa inqola ekhonjiwe noma amanye amathuluzi okuphatha afanelekile ukuze kuqinisekiswe ukuthuthwa ngokucophelela kwe-crucible.

Ukugcinwa kwe-Silicon Carbide kanye ne-Graphite Clay Crucibles: Ukugcinwa kwama-crucibles kusengozini yokulimala komswakama.

Ukuzijwayeza Okungalungile: Ukupakisha iziphambano ngokuqondile phansi usimende noma ukuzibeka emswakameni ngesikhathi sokugcinwa noma ukuthuthwa.

Ukuzijwayeza Okulungile:

Ama-crucibles kufanele agcinwe endaweni eyomile, okungcono kakhulu kuma-pallets enziwe ngokhuni, ukuqinisekisa ukungena komoya ngendlela efanele.

Lapho ama-crucibles ebekwe abheke phansi, angapakishwa ukuze konge isikhala.

Ama-crucibles akumele neze avezwe ezimeni ezinomswakama. Ukumuncwa komswakama kungabangela ukuthi ungqimba olucwebezelayo luxebuke phakathi nesigaba sokushisa, okuholela ekwehleni kokusebenza kahle nempilo yokuphila. Ezimweni ezimbi kakhulu, i-bottom of the crucible ingase ihlukane.

Inkampani yethu igxile ekukhiqizweni kwezinsimbi ze-silicon carbide graphite crucibles, izinsimbi ezikhethekile zokuncibilika kwe-aluminium, ama-copper graphite crucibles, ama-graphite clay crucibles, ama-graphite crucibles agxile kwamanye amazwe, amaconveyor e-phosphorus, izisekelo ze-graphite crucible, kanye nemikhono evikelayo yama-graphite. Imikhiqizo yethu ikhethwa ngokucophelela futhi ihlolwe, iqinisekisa ukusebenza kahle kusukela ekukhethweni kwezinto ezingavuthiwe kuye kuyo yonke imininingwane yokukhiqiza kanye nomklamo wokupakisha.

Isikhathi sokuthumela: Jun-27-2023