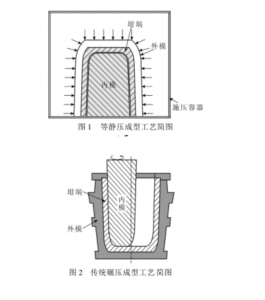

Ukukhiqizwa kwe-graphite crucible kuye kwavela ngokuphawulekayo ngokufika kobuchwepheshe bokucindezela be-isostatic, obumaka njengendlela ethuthuke kakhulu emhlabeni jikelele. Uma kuqhathaniswa nezindlela zendabuko zokunqanda, ukucindezela kwe-isostatic kuphumela ezitsheni ezinokwakheka okufanayo, ukuminyana okuphezulu, ukusebenza kahle kwamandla, kanye nokumelana okuphezulu ne-oxidation. Ukusetshenziswa kokucindezela okukhulu ngesikhathi sokubunjwa kuthuthukisa kakhulu ukuthungwa kwe-crucible, ukunciphisa i-porosity futhi kamuva kukhulisa ukuqhutshwa kwe-thermal nokumelana nokugqwala, njengoba kuboniswe kuMfanekiso 1. Endaweni ye-isostatic, ingxenye ngayinye ye-crucible ihlangabezana nengcindezi yokubumba iyunifomu, iqinisekisa ukuhambisana kwezinto kuyo yonke indawo. Le ndlela, njengoba ibonisiwe kuMfanekiso 2, idlula inqubo evamile yokunqanda, okuholela ekuthuthukisweni okukhulu ekusebenzeni okuqinile.

1. Isitatimende Senkinga

Ukukhathazeka kuphakama kumongo wesithando somlilo se-aluminium alloy insulation resistance kusetshenziswa izikhilimu ze-graphite ezinqanyuliwe, eziphila cishe izinsuku ezingu-45. Ngemuva kwezinsuku ezingama-20 kuphela zokusetshenziswa, ukwehla okubonakalayo kokusebenza okushisayo kuyabonakala, kuhambisane nemifantu emincane endaweni yangaphandle ye-crucible. Ezigabeni zakamuva zokusetshenziswa, ukwehla okukhulu kokusebenza kwe-thermal kubonakala, okunikeza i-crucible cishe i-non-conductive. Ukwengeza, imifantu eminingi ebusweni iyakhula, futhi ukushintsha kombala kwenzeka phezulu kwe-crucible ngenxa ye-oxidation.

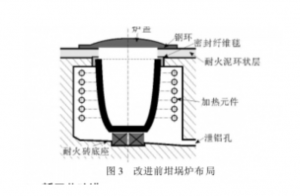

Lapho kuhlolwa isithando somlilo esiphehlayo, njengoba kuboniswe kuMfanekiso 3, isisekelo esakhiwe ngezitini ze-refractory ezistakiwe siyasetshenziswa, esinesici sokushisa esiphansi kunazo zonke sentambo yokumelana ebekwe ngo-100 mm ngaphezu kwesisekelo. Ingaphezulu le-crucible livalwe kusetshenziswa izingubo zokulala zefiber ye-asbestos, ezibekwe cishe ngo-50 mm ukusuka onqenqemeni olungaphandle, okuveza ukuhuzuka okubalulekile emaphethelweni angaphakathi onqenqema lwe-crucible.

2. Ukuthuthukiswa Okusha Kwezobuchwepheshe

Ukuthuthukiswa 1: Ukwamukelwa Kwe-Isostatic Cindezelwe Yobumba I-Graphite Crucible (Nge-Low-Temperature Resistant Oxidation Glaze)

Ukusetshenziswa kwalesi siphambano kuthuthukisa kakhulu ukusetshenziswa kwaso ezithandweni zokufakelwa kwe-aluminium ingxubevange, ikakhulukazi mayelana nokumelana ne-oxidation. I-graphite crucibles ivamise ukwenza i-oxidize emazingeni okushisa angaphezu kuka-400 ℃, kuyilapho izinga lokushisa lokufakwa kweziko le-aluminium alloy lisukela phakathi kuka-650 no-700 ℃. Ama-crucibles anobukhazikhazi obungavimbeli i-oxidation emazingeni aphansi angabambezela ngempumelelo inqubo ye-oxidation emazingeni okushisa angaphezu kuka-600 ℃, iqinisekise ukuqhutshwa kokushisa okuhle kakhulu kwesikhathi eside. Ngesikhathi esifanayo, ivimbela ukuncishiswa kwamandla ngenxa ye-oxidation, inweba impilo ye-crucible.

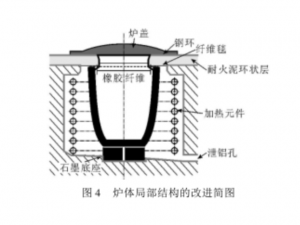

Ukuthuthukiswa 2: Isisekelo sesithando somlilo Ukusebenzisa iGraphite Yento efanayo njengeCrucible

Njengoba kuboniswe kuMfanekiso 4, ukusebenzisa isisekelo segraphite sento efanayo ne-crucible kuqinisekisa ukushisisa okufanayo kwephansi le-crucible ngesikhathi senqubo yokushisisa. Lokhu kunciphisa izinga lokushisa elibangelwa ukushisa okungalingani futhi kunciphisa ukuthambekela kokuqhekeka okubangelwa ukushisa okungaphansi okungalingani. Isisekelo se-graphite esizinikezele siphinde siqinisekise ukusekelwa okuzinzile kwe-crucible, ukuvumelanisa nephansi layo nokunciphisa ukuphuka okubangelwa ukucindezeleka.

Ukuthuthukiswa kwesi-3: Ukuthuthukiswa Kwesakhiwo Sendawo sesithando somlilo (Umfanekiso 4)

- Unqenqema oluthuthukisiwe lwangaphakathi lwekhava yesithando somlilo, kuvimbela ngempumelelo ukuguga phezulu kwe-crucible futhi kuthuthukisa ngokuphawulekayo ukuvala isithando somlilo.

- Ukuqinisekisa ukuthi intambo yokumelana ilingana nephansi le-crucible, okuqinisekisa ukushisisa okwanele okungaphansi.

- Ukunciphisa umthelela we-fiber blanket seal ephezulu ekushiseni okuqinile, ukuqinisekisa ukushisa okwanele phezulu kwe-crucible kanye nokunciphisa imiphumela ye-oxidation yezinga lokushisa eliphansi.

Ukuthuthukiswa kwesi-4: Ukucwenga Izinqubo Zokusetshenziswa Kwe-Crucible

Ngaphambi kokusetshenziswa, shisa kuqala i-crucible esithandweni emazingeni okushisa angaphansi kuka-200 ℃ amahora angu-1-2 ukuze ukhiphe umswakama. Ngemva kokushisa, phakamisa ngokushesha izinga lokushisa libe ngu-850-900 ℃, unciphise isikhathi sokuhlala phakathi kuka-300-600 ℃ ukuze unciphise i-oxidation ngaphakathi kwalolu banga lokushisa. Kamuva, yehlisa izinga lokushisa liye ezingeni lokushisa lokusebenza bese wethula uketshezi lwe-aluminium ukuze usebenze okuvamile.

Ngenxa yemiphumela eyonakalisayo yama-ejenti wokucwenga ezitsheni ezibethelwe phansi, landela imigomo yokusetshenziswa efanele. Ukususwa kwe-slag okuvamile kubalulekile futhi kufanele kwenziwe lapho i-crucible ishisa, njengoba ukuhlanza i-slag kuba inselele ngenye indlela. Ukubhekisisa ngokucophelela kokushisa kwe-crucible kanye nokuba khona kokuguga ezindongeni ezibethelekayo kubalulekile ezigabeni zakamuva zokusetshenziswa. Ukushintshwa okufika ngesikhathi kufanele kwenziwe ukuze kugwenywe ukulahleka kwamandla okungadingekile kanye nokuvuza kwe-aluminium liquid.

3. Imiphumela Yokuthuthukisa

Ubude bempilo obunwetshiwe be-crucible ethuthukisiwe buphawuleka, bugcina ukuguquguquka okushisayo isikhathi eside, ngaphandle kokuqhekeka kwendawo okubonwayo. Impendulo yomsebenzisi ibonisa ukusebenza okuthuthukisiwe, hhayi nje ukunciphisa izindleko zokukhiqiza kodwa futhi kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

4. Isiphetho

- Iziphambano ze-graphite zobumba ezicindezelwe yi-Isostatic zidlula izinsimbi zendabuko ngokusebenza.

- Isakhiwo sesithando somlilo kufanele sihambisane nosayizi nesakhiwo se-crucible ukuze usebenze kahle.

- Ukusetshenziswa okufanele kwe-crucible kwandisa kakhulu impilo yayo, kulawula ngempumelelo izindleko zokukhiqiza.

Ngokucwaninga okucophelela kanye nokwenza kahle kobuchwepheshe besithando somlilo, ukusebenza okuthuthukisiwe neminyaka yokuphila kunomthelela omkhulu ekwandiseni ukusebenza kahle kokukhiqiza nokonga izindleko.

Isikhathi sokuthumela: Dec-24-2023