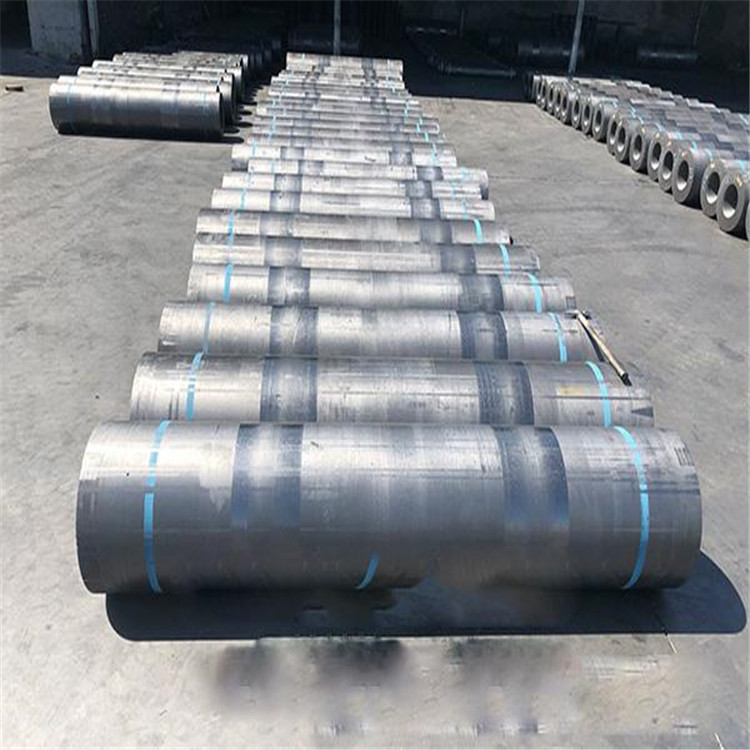

I-Graphite Electrodes

Ama-electrode e-graphite asetshenziswa embonini yokuncibilikisa kagesi futhi anezakhiwo ezifana ne-superconductivity, conductivity ezishisayo, amandla aphezulu emishini, ukumelana ne-oxidation, kanye nokumelana nokugqwala okuphezulu.

Ama-electrode ethu e-graphite anokumelana okuphansi, ukuminyana okuphezulu, ukumelana okuphezulu kwe-oxidation, nokunemba okunembile kwemishini, ikakhulukazi isibabule esiphansi nomlotha ophansi, ongeke ulethe ukungcola kwesibili ensimbi.

I-graphite inokusimama okuhle kwamakhemikhali. I-graphite ephathwe ngokukhethekile inezici zokumelana nokugqwala, ukuguquguquka okuhle kwe-thermal, nokungena kancane.

I-graphite electrode impahla eluhlaza isebenzisa isulfure ephansi kanye ne-CPC yomlotha ophansi. Engeza i-coke yenaliti engu-30% ku-electrode yebanga le-HP ye-asphalt yesitshalo se-coking. Ama-electrode e-graphite ebanga le-UHP asebenzisa i-coke yenaliti engu-100% futhi asetshenziswa kakhulu ku-LF. Isithando somlilo esenza insimbi, isithando somlilo esingeyona insimbi. Izimboni ze-silicon ne-phosphorus.

| Usayizi we-UHP nokubekezelelana | ||||||||||||

| Ububanzi (mm) | Ubude (mm) | |||||||||||

| Ububanzi bokuzisholo | Ububanzi bangempela | Ubude begama | Ukubekezelelana | Ubude bezinyawo ezimfushane | ||||||||

| mm | intshi | ubuningi | imiz | mm | mm | ubuningi | imiz | |||||

| 200 | 8 | 209 | 203 | 1800/2000/ 2200/2300 2400/2700 | ±100 | -100 | -275 | |||||

| 250 | 10 | 258 | 252 | |||||||||

| 300 | 12 | 307 | 302 | |||||||||

| 350 | 14 | 357 | 352 | |||||||||

| 400 | 16 | 409 | 403 | |||||||||

| 450 | 18 | 460 | 454 | |||||||||

| 500 | 20 | 511 | 505 | |||||||||

| 550 | 22 | 556 | 553 | |||||||||

| 600 | 24 | 613 | 607 | |||||||||

| Inkomba yePhysical and Chemical ye-UHP | ||||||||||||

| Izinto | iyunithi | Ububanzi: 300-600mm | ||||||||||

| Okujwayelekile | Hlola idatha | |||||||||||

| I-Electrode | Ingono | I-Electrode | Ingono | |||||||||

| Ukumelana nogesi | μQm | 5.5-6.0 | 5.0 | 5.0-5.8 | 4.5 | |||||||

| Amandla e-Flexure | Mpa | 10.5 | 16 | 14-16 | 18-20 | |||||||

| I-modulus ye-elasticity | I-GPa | 14 | 18 | 12 | 14 | |||||||

| Okuqukethwe komlotha | % | 0.2 | 0.2 | 0.2 | 0.2 | |||||||

| Ukuminyana okusobala | g/cm3 | 1.64-16.5 | 1.70-1.72 | 1.72-1.75 | 1.78 | |||||||

| Isici sokunwetshwa(100-600℃) | x10-6/°℃ | 1.5 | 1.4 | 1.3 | 1.2 | |||||||

Q: Kuthiwani ngokupakisha?

1. Amabhokisi amakhadibhodi ajwayelekile / amabhokisi e-plywood

2. Izimpawu zokuthumela ezenziwe ngokwezifiso

3. Uma indlela yokupakisha ingaphephile ngokwanele, umnyango we-QC uzokwenza ukuhlola