I-Graphite Crucibles Gold and Silver Melting Kit

IZICI ZOMKHIQIZO

I-Superior Thermal Conductivity

Inhlanganisela eyingqayizivele ye-silicon carbide ne-graphite iqinisekisa ukushisa okusheshayo nokufana okufanayo, ukunciphisa kakhulu isikhathi sokuncibilika.

I-Extreme Temperature Resistance

Inhlanganisela eyingqayizivele ye-silicon carbide ne-graphite iqinisekisa ukushisa okusheshayo nokufana okufanayo, ukunciphisa kakhulu isikhathi sokuncibilika.

Ukumelana Nokugqwala Okuqinile

Inhlanganisela eyingqayizivele ye-silicon carbide ne-graphite iqinisekisa ukushisa okusheshayo nokufana okufanayo, ukunciphisa kakhulu isikhathi sokuncibilika.

IMICIMBI YOBUCHWEPHESHE

| I-graphite / % | 41.49 |

| I-SiC / % | 45.16 |

| B/C / % | 4.85 |

| I-Al₂O₃ / % | 8.50 |

| Ukuminyana ngobuningi / g·cm⁻³ | 2.20 |

| I-porosity ebonakalayo / % | 10.8 |

| Amandla okuchoboza/MPa (25℃) | 28.4 |

| I-Modulus of rupture/ MPa (25℃) | 9.5 |

| Izinga lokushisa lokumelana nomlilo/℃ | > 1680 |

| Ukumelana nokushaqeka okushisayo / Izikhathi | 100 |

| Isimo/Ifomu | A (mm) | B (mm) | C (mm) | D (mm) | E x F ubuningi (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Ngesicelo |

| A | 1050 | 440 | 360 | 170 | 380x440 | Ngesicelo |

| B | 1050 | 440 | 360 | 220 | ⌀380 | Ngesicelo |

| B | 1050 | 440 | 360 | 245 | ⌀440 | Ngesicelo |

| A | 1500 | 520 | 430 | 240 | 400x520 | Ngesicelo |

| B | 1500 | 520 | 430 | 240 | ⌀400 | Ngesicelo |

UKUHAMBA KWENKQUBO

1. Ukunemba Ukwakhiwa

I-high-purity graphite + premium silicon carbide + i-ejenti ebophayo yobunikazi.

.

2.Isostatic Pressing

Ukuminyana kufika ku-2.2g/cm³ | Ukubekezelela ukuqina kwezindonga ± 0.3m

.

3.I-High-Temperature Sintering

I-SiC particle recrystallization yakha isakhiwo senethiwekhi ye-3D

.

4. Ukuthuthukisa Ubuso

I-Anti-oxidation coating → 3× ithuthukisiwe ukumelana nokugqwala

.

5.Ukuhlolwa Kwekhwalithi Okuqinile

Ikhodi yokulandelela eyingqayizivele yokulandeleka okugcwele komjikelezo wempilo

.

6.Ukuphepha Packaging

Isendlalelo esimunca ukushaqeka + Isivimbeli somswakama + Ikesi lebhokisi eliqinisiwe

.

ISICELO SOMKHIQIZO

Isithando Somlilo Esincibilikisa Igesi

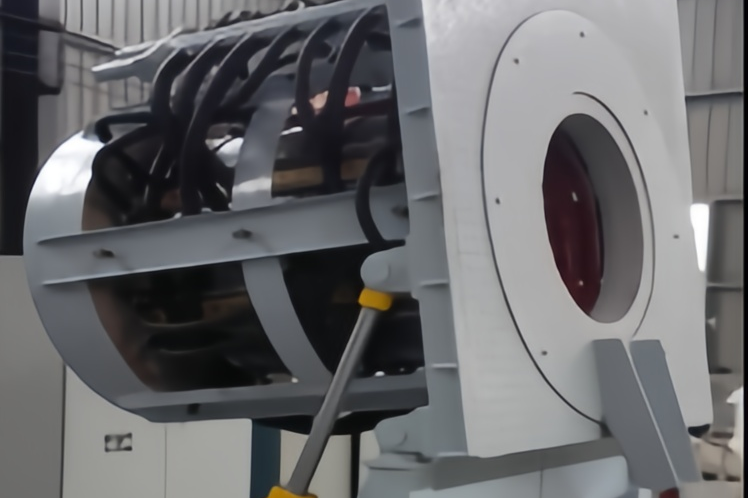

I-Induction Melting Furnace

I-Resistance Melting Furnace

KUNGANI SIKHETHE

FAQS

I-Q1: Yiziphi izinzuzo ze-silicon carbide graphite crucibles uma kuqhathaniswa nezinsimbi ze-graphite zendabuko?

✅I-Higher Temperature Resistance: Ingakwazi ukumelana ne-1800 ° C yesikhathi eside kanye ne-2200 ° C yesikhashana (vs. ≤1600 ° C ye-graphite).

✅Ukuphila Okude: 5x ukumelana nokushaqeka okushisayo okungcono, 3-5x impilo yesevisi emaphakathi ende.

✅Zero Ukungcola: Akukho ukungena kwekhabhoni, kuqinisekisa ubumsulwa bensimbi encibilikisiwe.

Q2: Yiziphi izinsimbi ezingancibilika kulezi zinsimbi?

▸Izinsimbi Ezivamile: I-aluminium, ithusi, i-zinc, igolide, isiliva, njll.

▸Izinsimbi EzisebenzayoI-Lithium, i-sodium, i-calcium (idinga i-Si₃N₄ enamathela).

▸Izinsimbi Refractory: I-Tungsten, i-molybdenum, i-titanium (idinga i-vacuum/inert gas).

Q3: Ingabe ama-crucible amasha adinga ukwelashwa kusengaphambili ngaphambi kokusetshenziswa?

Ukubhaka Okuphoqelekile: Shisisa kancane ku-300°C → bamba amahora angu-2 (isusa umswakama osele).

Okokuqala Melt Isincomo: Ncibilikisa inqwaba yezinto ezilahliwe kuqala (yakha isendlalelo esivikelayo).

Q4: Ungakuvimbela kanjani ukuqhekeka kwe-crucible?

Ungalokothi ushaje into ebandayo ku-crucible eshisayo (ubukhulu ΔT <400°C).

Izinga lokupholisa ngemva kokuncibilika ngaphansi kuka-200°C/ihora.

Sebenzisa ama-crucible tongs (gwema umthelela wemishini).

Q5: Ungakuvimbela kanjani ukuqhekeka kwe-crucible?

Ungalokothi ushaje into ebandayo ku-crucible eshisayo (ubukhulu ΔT <400°C).

Izinga lokupholisa ngemva kokuncibilika ngaphansi kuka-200°C/ihora.

Sebenzisa ama-crucible tongs (gwema umthelela wemishini).

Q6: Ithini inani elincane le-oda (MOQ)?

Amamodeli Ajwayelekile: 1 ucezu (amasampula ayatholakala).

Imiklamo Yangokwezifiso: Izingcezu eziyi-10 (imidwebo ye-CAD iyadingeka).

Q7: Sithini isikhathi sokuhola?

⏳Izinto Ezisesitokweni: Ithunyelwa emahoreni angama-48.

⏳Ama-oda ngokwezifiso: 15-25izinsukuukukhiqizwa kanye nezinsuku ezingama-20 zokukhunta.

Q8: Unganquma kanjani ukuthi i-crucible yehlulekile?

Imifantu > 5mm odongeni lwangaphakathi.

Ukujula kokungena kwensimbi > 2mm.

Ukuguqulwa > 3% (linganisa ukushintsha kobubanzi bangaphandle).

Q9: Ingabe uyasinikeza isiqondiso senqubo yokuncibilika?

Amajika okushisa ezinsimbi ezahlukene.

Isibali sesilinganiso sokugeleza kwegesi engenzi lutho.

Izifundo zevidiyo zokususa i-Slag.