Lorem ipsum dolor sit amet, consectetur adipiscing elit. I-Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

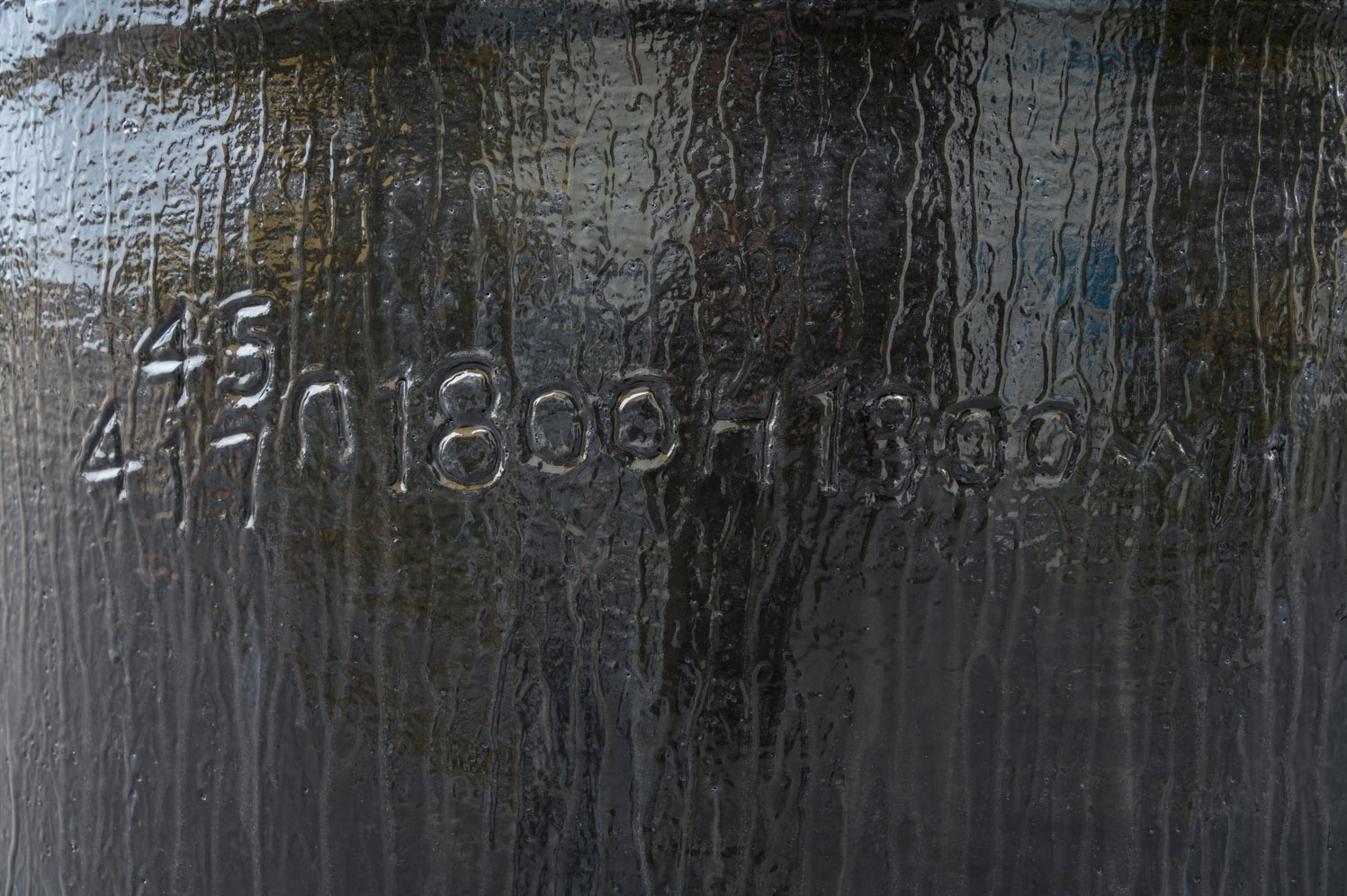

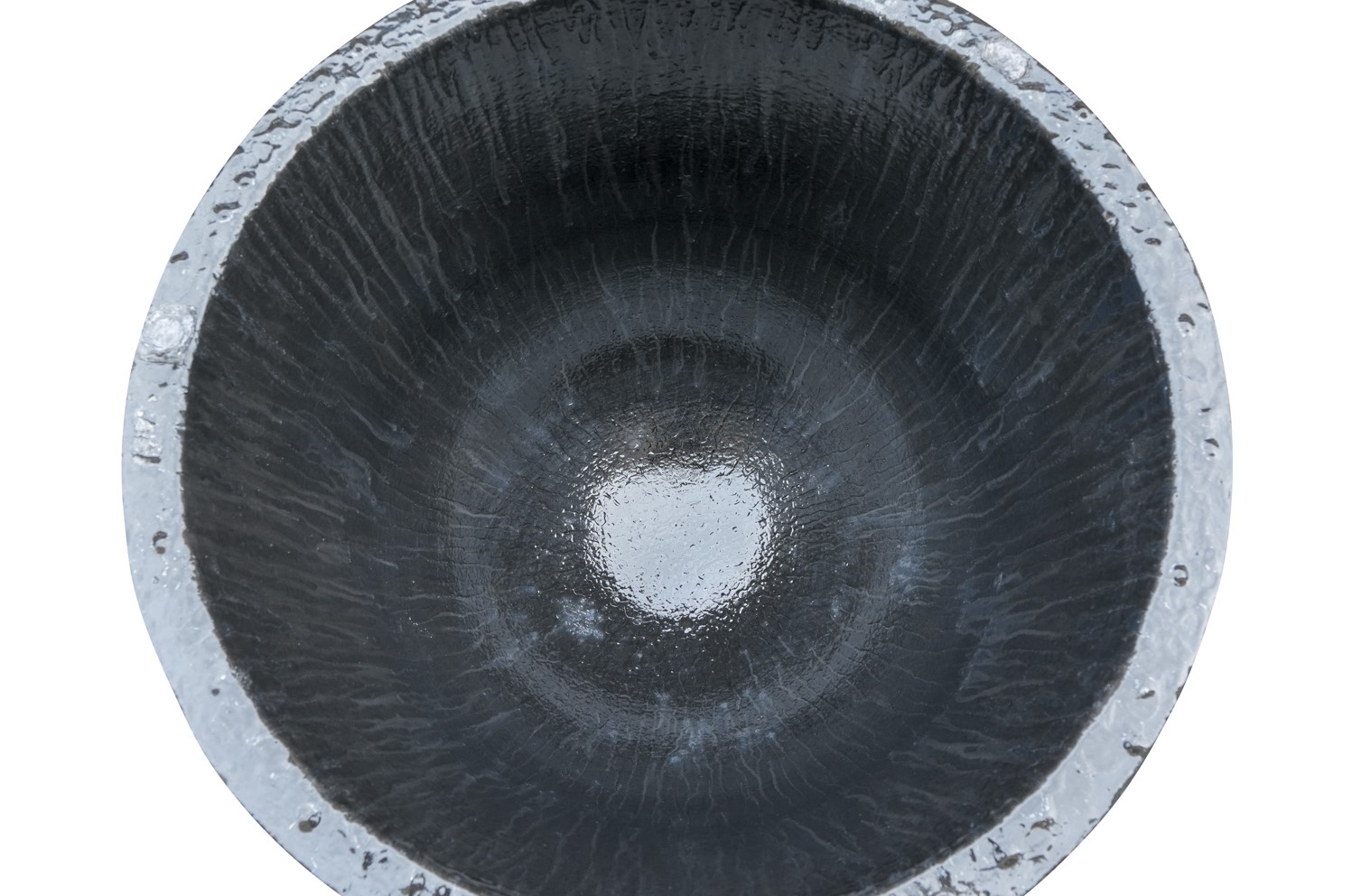

I-Die Casting Crucible ye-Aluminium Die Casting

IZICI ZOMKHIQIZO

Ukuncibilika Okusheshayo

I-high conductivity eshisayo ye-graphite impahla ithuthukisa ukusebenza kahle kokushisa ngama-30%, kunciphisa kakhulu isikhathi sokuncibilika.

I-Superior Thermal Shock Resistance

Ubuchwepheshe obuboshwe nge-resin bumelana nokushisisa nokupholisa okusheshayo, okuvumela ukushaja okuqondile ngaphandle kokuqhekeka.

Ukuqina Okuyingqayizivele

Amandla aphezulu emishini amelana nomthelela womzimba kanye nokuguguleka kwamakhemikhali impilo ende yesevisi.

IMICIMBI YOBUCHWEPHESHE

| I-graphite / % | 41.49 |

| I-SiC / % | 45.16 |

| B/C / % | 4.85 |

| I-Al₂O₃ / % | 8.50 |

| Ukuminyana ngobuningi / g·cm⁻³ | 2.20 |

| I-porosity ebonakalayo / % | 10.8 |

| Amandla okuchoboza/MPa (25℃) | 28.4 |

| I-Modulus of rupture/ MPa (25℃) | 9.5 |

| Izinga lokushisa lokumelana nomlilo/℃ | > 1680 |

| Ukumelana nokushaqeka okushisayo / Izikhathi | 100 |

| No | Imodeli | H | OD | BD |

| I-RA100 | 100# | 380 | 330 | 205 |

| I-RA200H400 | 180# | 400 | 400 | 230 |

| I-RA200 | 200# | 450 | 410 | 230 |

| I-RA300 | 300# | 450 | 450 | 230 |

| I-RA350 | 349# | 590 | 460 | 230 |

| I-RA350H510 | 345# | 510 | 460 | 230 |

| I-RA400 | 400# | 600 | 530 | 310 |

| I-RA500 | 500# | 660 | 530 | 310 |

| I-RA600 | 501# | 700 | 530 | 310 |

| I-RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

UKUHAMBA KWENKQUBO

1. Ukunemba Ukwakhiwa

I-high-purity graphite + premium silicon carbide + i-ejenti ebophayo yobunikazi.

.

2.Isostatic Pressing

Ukuminyana kufika ku-2.2g/cm³ | Ukubekezelela ukuqina kwezindonga ± 0.3m

.

3.I-High-Temperature Sintering

I-SiC particle recrystallization yakha isakhiwo senethiwekhi ye-3D

.

5.Ukuhlolwa Kwekhwalithi Okuqinile

Ikhodi yokulandelela eyingqayizivele yokulandeleka okugcwele komjikelezo wempilo

.

4. Ukuthuthukisa Ubuso

I-Anti-oxidation coating → 3× ithuthukisiwe ukumelana nokugqwala

.

6.Ukuphepha Packaging

Isendlalelo esimunca ukushaqeka + Isivimbeli somswakama + Ikesi lebhokisi eliqinisiwe

.

ISICELO SOMKHIQIZO

Ifanele izinsimbi eziningi ezingenayo insimbi

Ncibilikisa i-Aluminium

Melt Copper

Ncibilikisa Igolide

KUNGANI SIKHETHE

FAQS

Q1: Ingabe I-Crucible Cover inganciphisa izindleko zamandla?

A: Nakanjani! Yehlisa ukulahlekelwa ukushisa, inciphise ukusetshenziswa kwamandla kufika ku-30%.

Q2: Yiziphi izithando ezihambisanayo?

IMP: Iguquguquka—ifanele ukungeniswa, igesi, neziko likagesi.

I-Q3: Ingabe i-graphite silicon carbide iphephile emazingeni okushisa aphezulu?

A: Yebo. Ukuzinza kwayo okushisayo namakhemikhali kuyenza ifanelekele izimo ezimbi kakhulu.

Q4: Ungakuvimbela kanjani ukuqhekeka kwe-crucible?

Ungalokothi ushaje into ebandayo ku-crucible eshisayo (ubukhulu ΔT <400°C).

Izinga lokupholisa ngemva kokuncibilika ngaphansi kuka-200°C/ihora.

Sebenzisa ama-crucible tongs (gwema umthelela wemishini).

Q5: Ungakuvimbela kanjani ukuqhekeka kwe-crucible?

Ungalokothi ushaje into ebandayo ku-crucible eshisayo (ubukhulu ΔT <400°C).

Izinga lokupholisa ngemva kokuncibilika ngaphansi kuka-200°C/ihora.

Sebenzisa ama-crucible tongs (gwema umthelela wemishini).

Q6: Ithini inani elincane le-oda (MOQ)?

Amamodeli Ajwayelekile: 1 ucezu (amasampula ayatholakala).

Imiklamo Yangokwezifiso: Izingcezu eziyi-10 (imidwebo ye-CAD iyadingeka).

Q7: Sithini isikhathi sokuhola?

⏳Izinto Ezisesitokweni: Ithunyelwa emahoreni angama-48.

⏳Ama-oda ngokwezifiso: 15-25izinsukuukukhiqizwa kanye nezinsuku ezingama-20 zokukhunta.

Q8: Unganquma kanjani ukuthi i-crucible yehlulekile?

Imifantu > 5mm odongeni lwangaphakathi.

Ukujula kokungena kwensimbi > 2mm.

Ukuguqulwa > 3% (linganisa ukushintsha kobubanzi bangaphandle).

Q9: Ingabe uyasinikeza isiqondiso senqubo yokuncibilika?

Amajika okushisa ezinsimbi ezahlukene.

Isibali sesilinganiso sokugeleza kwegesi engenzi lutho.

Izifundo zevidiyo zokususa i-Slag.

Isifundo #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. I-Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Isifundo #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. I-Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Ubufakazi

Lorem ipsum dolor sit amet, consectetur adipiscing elit. I-Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. I-Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. I-Nullam id scelerisque magna. I-Curabitur placerat sodales placerat. I-Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. I-Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. I-Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. I-Nullam id scelerisque magna. I-Curabitur placerat sodales placerat. I-Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- UJohn Doe